PPF the Right Way on this brand new Tesla Model Y Juniper

It's an automotive sticker. How hard can PPF be on my new Tesla?

“Let Me Show You How We Protected This Tesla Model Y the Right Way”

When a brand-new Tesla Model Y rolls into my shop, my first thought is always the same: Let’s make sure it stays looking brand new for as long as possible.

That was exactly the mission with this pearl white Model Y. The owner wanted long-term protection—something that could take the abuse of daily driving without ruining the clean, factory look of the car. So we went with one of the most effective tools in the industry: paint protection film, or PPF.

Now, if you're not super familiar with PPF, let me explain why I love it and why we install it the way we do.

Why I Recommend PPF Over Everything Else

PPF is a thick, self-healing film that goes directly over your vehicle’s paint. Unlike ceramic coatings, which mostly add gloss and slickness, PPF is all about physical durability.

You know those rock chips you get from highway driving?

PPF takes those hits.

Bug splatter and acidic bird droppings that etch into your clear coat?

PPF blocks them.

Brushes from shrubs when backing out of tight spaces, sand kicked up from trucks, even light scratches from fingernails or car washes—PPF eats it all.

And if it gets scratched? Heat or sunlight usually “heals” it right back.

To put it bluntly: it saves your paint. And a proper repaint—especially on a Tesla—isn’t cheap. A hood respray alone can cost anywhere from $1,200 to $2,500 and still might not match perfectly.

So why not prevent that bill altogether?

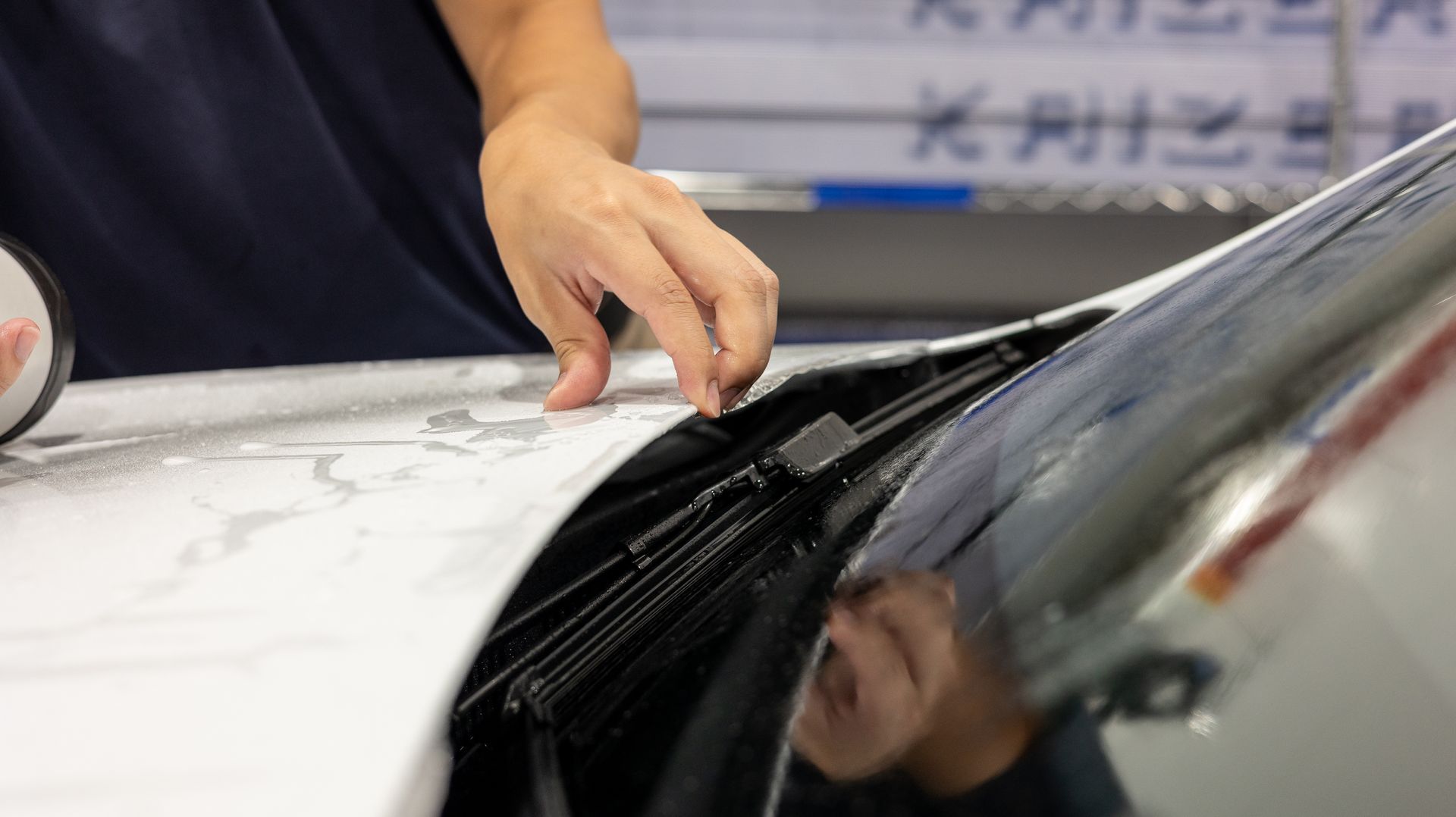

We Start With a Deep Decontamination—Not Just a Wash

Before we even think about laying film, the first step is always prep. And when I say prep, I don’t just mean a quick soap and rinse. I’m talking about chemical decontamination that breaks down everything hiding in or on the paint.

This Model Y got:

- Bug remover on the front clip to soften and remove acidic insect residue

- Iron remover (we used IronX here) to chemically dissolve embedded metal particles—those come from brake dust and industrial fallout

- A full foam pre-soak, followed by a contact wash with clean mitts

- Rinsing into every crevice—like under the windshield trim and inside fender gaps—so we don’t trap dirt under the film

If you skip this part, the film won’t lay clean. Worse, it might lift early or seal in debris that ruins the look. That’s not acceptable for me or for my clients.

Tesla Detailing Plano 1

A full three-bucket wash is included with every service from Humble Crew Auto Spa in Plano.

Tesla Detailing Plano 2

CarPro Bug Out dissolves imbedded bug guts in the paint, allowing us to fully remove the contaminant.

Tesla Detailing Plano 3

Iron Decontamination removes stubborn iron and dissolves them purple, which is then rinsed off the paint for a clean surface.

Here’s Where We Go the Extra Mile—Tucked Edges Matter, Especially on White

Now let’s talk about what really separates a pro install from a mediocre one: the edges.

You’ve probably seen PPF jobs where there’s a visible line a few millimeters from the edge of the panel. On dark cars, it’s not the end of the world. But on white paint? It’s a magnet for dirt. That border turns into a black outline in no time.

That’s why I

tuck every edge I can.

That means stretching the film slightly past the panel and wrapping it cleanly underneath so the film ends out of sight. No edge = no grime line = clean appearance long term.

Now, to pull that off properly, we even take it one step further...

Yes, We Remove the Front Wheel Arch Liners (And Here’s Why That Matters)

On this car, we removed the front wheel well liners and plastic cladding so we could wrap the film deep into the fender lips.

Why?

Because most installers just stop at the visible edge. But behind the scenes, there’s exposed paint that still gets blasted by road debris. We protect that too.

It’s an extra step that costs us time—but here’s the tradeoff:

- You get film that stays tucked

- You get no peeling or lift-down the line

- And you end up with true edge-to-edge coverage even where most won’t bother

I tell clients all the time: PPF is only as good as the installer behind it. And details like this are where that craftsmanship shows.

We Cut Corners—The Right Way

Corners are one of the most overlooked parts of a PPF install—but they’re also one of the most failure-prone if done incorrectly. It’s where three different planes of a panel come together, and where film has to stretch, fold, or contour in multiple directions at once.

If you try to force the film over a tight corner without proper relief cuts, you’ll end up with one of three problems:

- Bunching or overlap, which looks sloppy and creates a thick buildup that stands out visually

- Tension lines, which can eventually pull the film back or cause lifting, especially in high-heat environments

- Micro-stretching, where the adhesive loses its bond because the film is too thin or distorted in the corner

So instead of stretching the film and hoping it holds, I take a different approach.

What I do is strategic corner relief cutting. That means I’ll lay the film, then make micro-incisions—almost like surgical flaps—at calculated angles depending on the curvature and thickness of the panel. These relief cuts allow the material to “fall into place” without any tension. From there, I heat set and gently stretch each flap just enough to tuck it cleanly behind the edge without creating bulk or visible seams.

It’s slow. It’s tedious. But it makes a night and day difference in the final result.

You’ll notice in the photos:

- There’s no visible film edge curling around the corner

- The corner follows the natural contour of the panel

- There are fewer lift points, even under close inspection

Each cut is deliberate. Each corner is heat-locked after install to make sure it stays down long-term. No flags. No rework. No comebacks.

I treat corners the same way I’d treat stitching on a custom suit—clean, symmetrical, and invisible. Because once the rest of the install is perfect, it’s those little spots that your eyes go to first. And I’d rather you see nothing at all.

The Finished Result: Invisible, Durable, and Clean

When we finished this Model Y, you couldn’t tell anything was on it. That’s the point. It still looked like a brand-new Tesla—but now it had stealth protection baked in.

- The hood edges were fully tucked

- Every corner was tight and smooth

- No lifted edges, no exposed seams, no “halo” lines on the white paint

- And most importantly, it’s now protected from the road ahead

Wrapping Up

If you’re reading this and thinking about protecting your Tesla—or any other high-end car—you deserve an install that’s done right. No shortcuts. No gimmicks. Just clean, methodical craftsmanship from start to finish.

We’re not the cheapest in town—and we’re proud of that. Because every corner I cut (literally) and every edge I tuck is one more reason your car’s going to look flawless five years from now.

If you want that kind of peace of mind, let’s set up a consultation.

— Jesse

Humble Crew Auto Spa