PPF on a new Tesla Model Y Juniper: Trickier than it looks

Restoring an Icon

Protecting the Future: Full Front-End PPF on a 2026 Tesla Model Y Juniper

The 2026 Tesla Model Y “Juniper” edition has finally landed in the United States — and Humble Crew Auto Spa was among the first to protect one with a full front-end paint protection film (PPF) installation. This latest Model Y refresh, which originally debuted in China, brings a host of visual and performance enhancements, including redesigned bodywork, an illuminated front light bar, a revised trunk, and an upgraded interior featuring enhanced glass, audio, and tech.

Naturally, a vehicle this cutting-edge deserves an equally premium layer of protection. That’s where Humble Crew’s meticulous PPF process comes in.

Every Installation Starts With a Deep Clean

Before any film touches the paint, Jesse and the team begin with a full decontamination wash. This includes a three-bucket method — two buckets dedicated to the paint and one for wheels — plus thorough brushwork in all crevices and tight areas. The surface is also treated with a clay bar to remove embedded contaminants, ensuring the film adheres perfectly without any interference.

Going Beyond Standard PPF: What Sets This Install Apart

One of the biggest differences between a standard PPF job and what Humble Crew delivers is in the custom tuck patterns. For the Juniper Model Y, the team extended the film well beyond the visible edge of the panel. This required manually adjusting the plot files, a step many shops skip due to the added time and complexity.

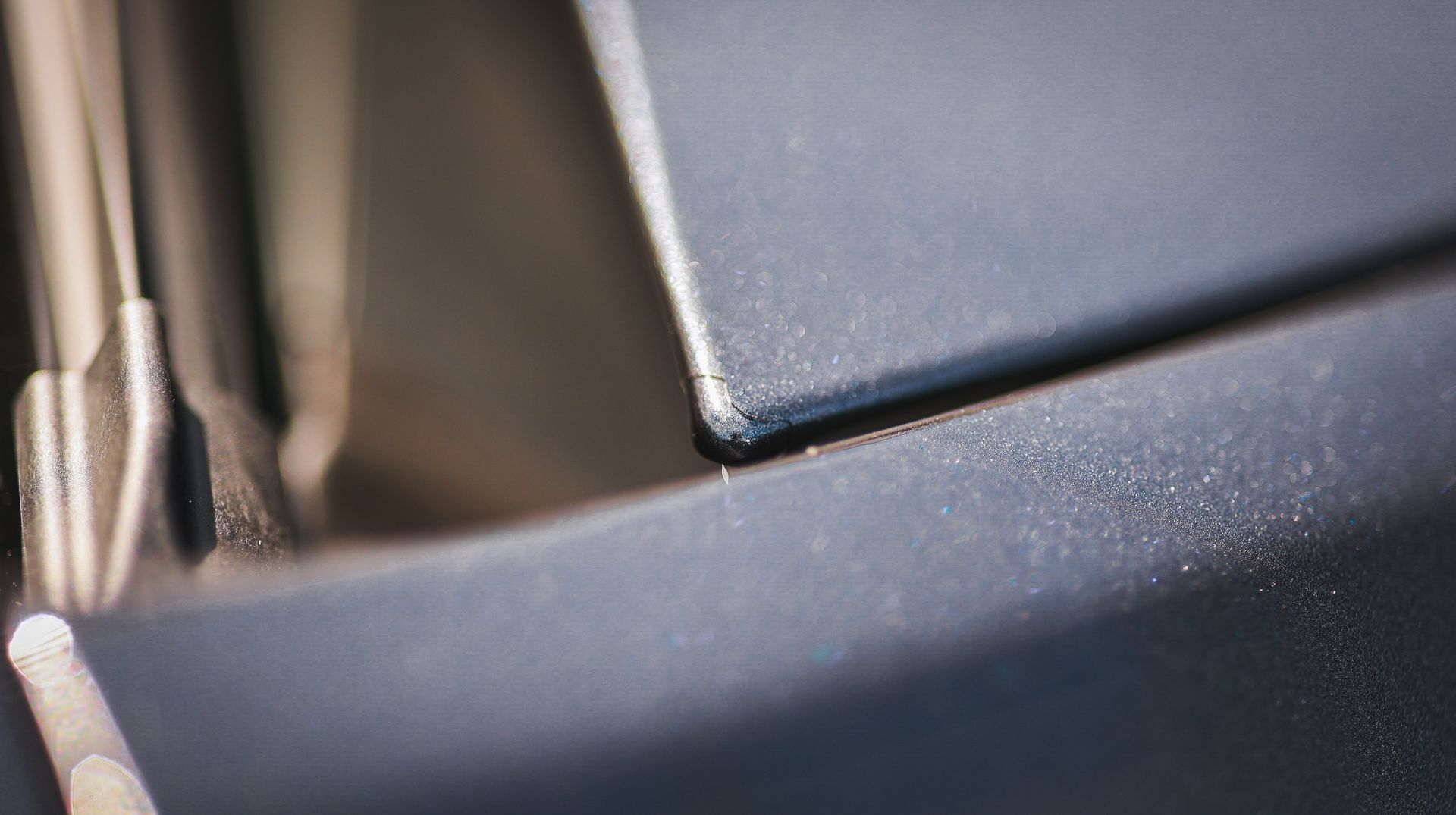

By removing the plastic cladding in the wheel wells and manually stretching the film to tuck deep into panel gaps, Humble Crew significantly enhances the film's durability — especially in vulnerable lower areas where lifting and catching are more likely over time.

Micro Adjustments for Macro Results

The team also custom-modified sensor cutouts, trimming them by as little as 0.125 inches to ensure tighter fits around the car’s ADAS sensors. This small but crucial tweak minimizes exposed edges and maintains a cleaner, OEM-like finish.

Hood Installation: Precision and Planning

Interestingly, although Humble Crew typically bulks hoods, the geometry of the new Juniper Model Y made a cutout pattern a more precise fit. The near-square hood profile allowed the pre-cut film to land perfectly on corners and edges, tucking flush with no trimming needed.

The install continued across the fenders and bumper, with every section dry-fitted and aligned before locking into place. This method ensures symmetrical fitment across all points — from the top corners down to the lower intakes.

Careful Stretching, Clean Tucking

The bumper install was a standout part of the project. The team used a combination of hot tack solution (essentially hot water) and precise hand-squeegeeing to work the film into tight edges, curves, and lower lips. Every lift, pull, and lock-in was planned and executed with the tension points in mind, minimizing risk of tearing or long-term lifting.

The seams were held in place using just the heat from the installer’s hands, often supplemented with heat guns or additional tack spray where necessary.

The Importance of Water Evacuation

Jesse’s method emphasized one golden rule: never lock in water behind the film. Throughout the install, the team paused to check for trapped air and moisture before squeegeeing, especially around seams and high-tension zones. In one key moment, Jesse catches a hidden water bubble just in time, redirecting it to the edge before sealing it in permanently.

Tucked Edges = Longer Life

One of the major advantages of Humble Crew’s method is the fully tucked film edges — especially on the bumper and lower rocker sections. Where other installers might trim the film flush, Jesse’s team tucks it fully under the cladding and lips. This gives the film a cleaner look and drastically reduces the chance of lifting from wear, weather, or car washes.

Mirror Install: Kit vs Bulk

The Juniper Model Y’s mirrors posed a unique challenge. With a pronounced recess dividing the housing, the usual bulk install wasn’t ideal. Instead, the team opted for a pre-cut kit pattern that hugged the recesses cleanly, ensuring both aesthetics and longevity.

Final Steps: Heat Curing and Trimming

With the film laid down and tucked, the final step was a thorough heat treatment across all edges and seams. This activates the adhesive and ensures long-term bonding. Any excess film or lift-prone areas were also trimmed or re-tacked to eliminate future issues.

The Finished Result

The end result? A 2026 Tesla Model Y Juniper with a nearly invisible armor of protection. The film is tucked, clean, and dialed in — offering long-lasting protection from rock chips, road debris, and UV damage.

Jesse and the Humble Crew Auto Spa team go beyond the standard PPF install. Their obsessive attention to detail and willingness to take extra steps — from custom plotting to edge tucking — translates into better protection, better durability, and better-looking results.

Want This for Your Tesla?

If you’re taking delivery of a 2026 Model Y or any high-end vehicle and want the most thorough and durable paint protection available, this is the method that gets it done. Book your appointment at Humble Crew Auto Spa today — where craftsmanship meets car care.

Would you like me to turn this into a downloadable PDF, WordPress blog draft, or even generate meta title/description and Open Graph preview tags for SEO and social sharing?