Full color PPF completely changes this 718 Spyder

$12000 PPF WRAP

Full Color PPF completely changes this Porsche 718 Spyder

What happens when you combine the best form of paint protection with a unique finish that resembles a high end paint job? That's what Jesse wanted with his new-to-him Porsche 718 Spyder. We transformed his car with a full-body Ultrafit Phoenix Red color PPF installation.

The process was superbly grueling, and this project took over 100 man hours of labor, involving full disassembly, bulk film installation, edge wrapping, and a finish that looks indistinguishable from custom paint. Here’s how we did it.

Why Ultrafit Phoenix Red?

Ultrafit’s Phoenix Red delivers on all fronts:

- A head-turning color shift and high-gloss finish that goes from Burgundy into a deep Gold color

- Durable self-healing surface

- UV protection and long-term clarity

- And most importantly: PPF-level impact protection with the look of a luxury repaint

It’s the best of both worlds: style and substance.

Disassembly: Total Panel Access. Prepare your wrenches.

To achieve a flawless look, we fully disassembled the Porsche — a step skipped by many but absolutely essential for pro-level results.

Front Bumper

We removed the wheels and wheel liners, detached the underbody screws and frunk bolts, popped out the side markers, removed the headlights, and gently slid the bumper off after disconnecting electricals — all to ensure the bumper could be fully wrapped without seams or exposed edges.

Rear Bumper (I hate this part the most):

Taking off the rear bumper is a bit of a process. First, we remove the spoiler to access the tail lights. Once the tail lights are out, we can get to the bolts that hold on the Porsche light bar that runs across the back — that comes off next.

After that, we remove all the bolts and clips holding the bumper on, including some underneath and inside the fender liners. Once everything is disconnected, we carefully pull the bumper off.

Removing the rear bumper on the 718 Spyder is already a bit of a process — but separating the rear diffuser from the bumper is honestly one of the biggest headaches. That diffuser is tightly secured with clips and bolts, and it sits in some pretty tight spots, so getting it apart without damaging anything takes patience and finesse.

You have to carefully work around hidden fasteners and use pry tools to loosen it without cracking or scratching the parts. It’s a slow, delicate job, but it’s totally worth it because separating those pieces lets us wrap the rear bumper perfectly and tuck the film edges out of sight for a clean, factory finish.

Door Handles:

To get the door handles off, we first take off the interior door panel. Once that’s out of the way, we can reach behind and disconnect the rods and cables that link the handle to the latch. After that, it’s just a couple of bolts and the handle slides out from the outside.

Side Mirrors:

For the mirrors, we pop off the little triangular trim piece on the inside of the door. That gives us access to the bolts holding the mirror in place. We unplug the wiring (for power and heating), undo the bolts, and then pull the mirror straight off.

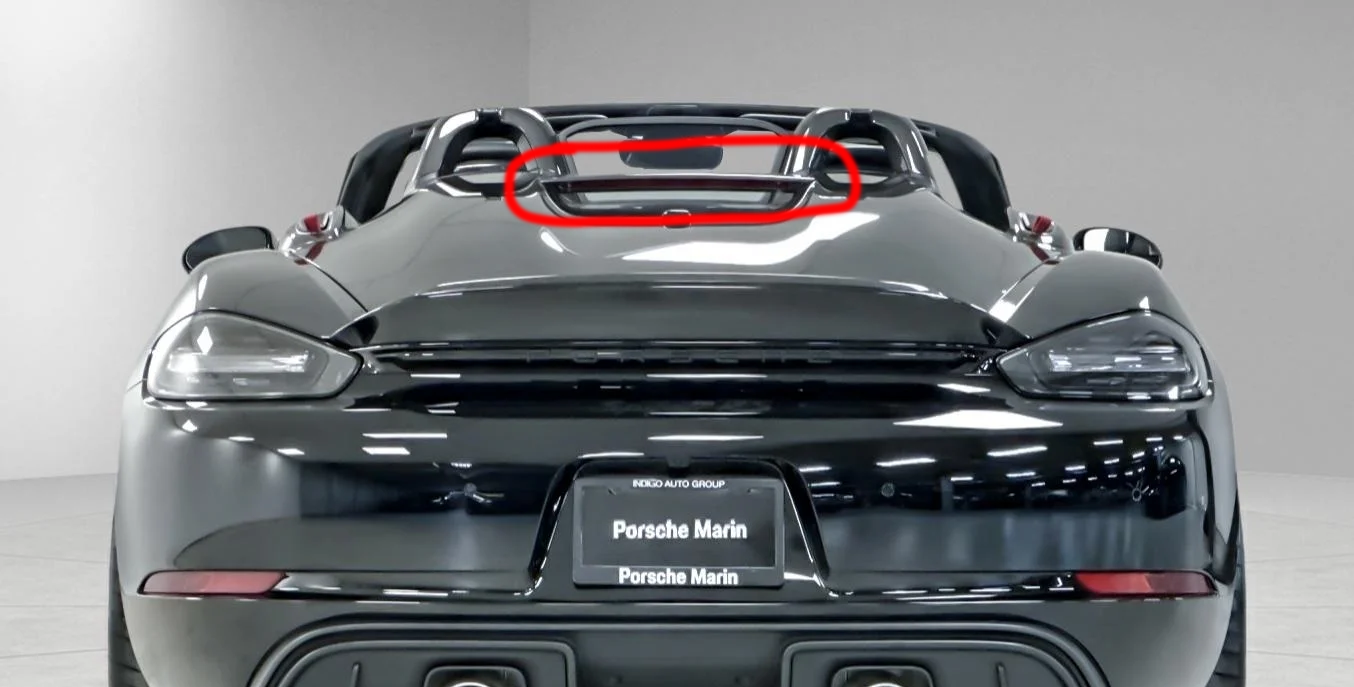

Disassembling the Rear Plastic Bar Between the Trunk “Humps”:

On the Spyder’s rear trunk, there’s a plastic bar that connects the two raised humps near the roll hoop covers. This piece needs to be removed to fully access and protect the trunk area during the PPF install.

Removing it involves carefully loosening several hidden bolts and clips that secure the bar in place. Because it fits snugly between the humps and under the roll hoops, it takes some patience to gently pry it free without damaging the plastic or surrounding paint. Once removed, it exposes the full surface so we can wrap the film cleanly around these complex curves and edges.

This step is tricky but necessary for full coverage without any seams, and cannot be done without this tedious step.

So with all of that out of the way, now we can finally get to laying some film.

This is where expertise matters. We did a bulk installation, which means minimal pre-cut kits, no shortcuts — just precision film handling with every piece custom-fitted by hand.

Squeegee Technique

Every installer has their style, but here are our key principles:

- Soft-edge squeegees are ideal for initial lay-downs to avoid micro-scratches.

- Firm-edge squeegees (using the backside of our rubber squeegees) are used to push out slip solution and seal the film to the surface. This step is important, and we do it as an "insurance" swipe to get rid of any small bubbles that might've slipped our eyes.

- We always work

from the center outward, using overlapping passes in controlled, even pressure strokes — never dragging too far or skipping zones to prevent air trapping.

Edge and Corner Wrapping

Corners are where most installs fail — but here’s how we make ours disappear:

- Overwrap the edge by ¼–½ inch, then post-heat gently.

- Use a sharp blade to relieve the corner with a single 45° cut right underneath the corner perimeter, on the bottom side. This gives us a very tight corner that either tucks or goes all the way to the edge of the panel.

- Tuck each flap down separately using a soft glove or squeegee tip, then seal it with heat to lock it in place.

This keeps corners tight, clean, and resistant to peeling or lifting over time.

Post-Installation Cleanup & Lock-In Process

A PPF job isn’t finished when the film’s on — the finish work is where the job earns its value.

- Post-heating: Every wrapped edge and corner is gently reheated to activate the adhesive and “lock in” the film, preventing future lifting.

- Edge sealing: We inspect all door jambs, gas caps, hood lines, and wheel arches to ensure no moisture or air remains trapped. This is done at the same time as the post-heating step.

- Panel alignment check: Everything we removed earlier needs to go back on. After reassembly, we confirm that all removed parts fit flush, ensuring OEM-level appearance. On German cars in particular, if your clips aren't 100% lined up, you'll see the fitment slightly off, striking your OCD alarm. Let's just say we sat there for a while and stared at the car over a less-than-1mm gap.

Holy cow we are done.

After over 100 hours of labor, we are done with this install. It was beyond tedious, and completely non-standard for PPF installs (most of the time). With color PPF, you really can't get away with a standard install, as the original color will poke through if you don't get full coverage. The end result is a car that really turns heads at car shows, all while being fully protected from most of the wear and tear it'll experience on the roads and on the track (that's right, Jesse tracks this car).

Color PPF is one of the most labor and skill intensive trades in this field, requiring patience, precision, and technique. The idea here is that if we're good at color PPF, we're probably pretty decent at regular clear bra too.

Speaking of which, if you want to get your car with us, you can send us an inquiry by clicking

here. Talk to you soon!